INCREASING BIOGAS OUTPUT BY PREVENTING COSTLY SHUT-DOWNS

Transform the way you manage your

biogas production:

No personnel working in confined spaces with potential trapped gas

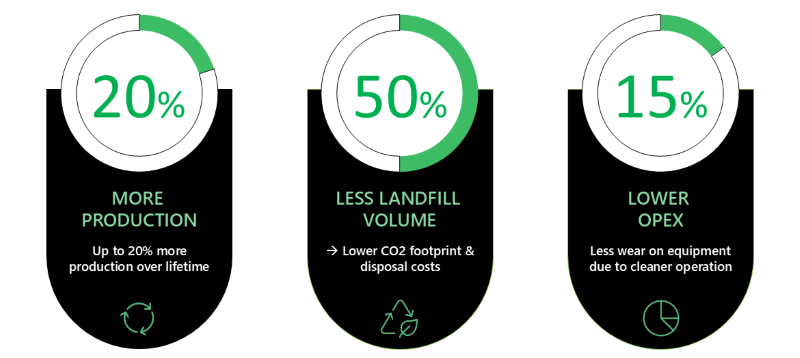

50% reduction in landfill volumes

Lower maintenance cost due to less sand in system

Removing sand at regular intervals keeps production high

Traditionally, digestors are run until they are full, before stopping to clean them due to the cost and heavy labor it requires - removing sand at regular intervals, keeping the total volume of sand low, will increase gas production during the full production cycle.

Our Solution

how it works

Sand Removal Service

Sand removal operation by the use of wash out and separation technology adapted from the oil and gas industry.

By entering though as service valve we are able to remove the sand and return the slurry back to the digestor for further gas production, increasing volumes available to slurries

In-Tank washing head

Output fragments during operation

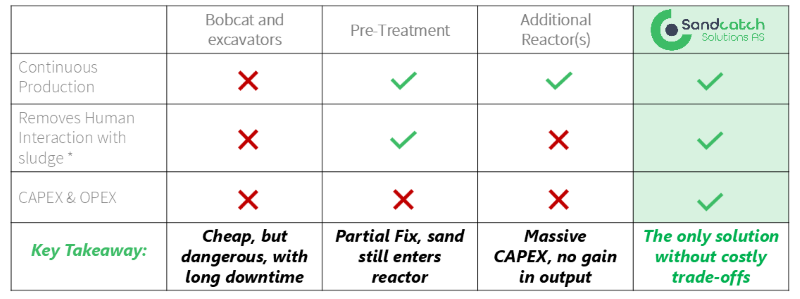

The Only Solution Without Costly Trade-offs

Whiles other solutions to the sand build-up in digestors do exist, they all have trade off, either linked to cost, efficiency og HSE risks. Sandcatch Solutions offers a solution which involves no human interaction with sludge, no shut down of production and no costly additional equipment to be installed after production stat-up

Meet the team

CECILIE DRANGE

CEO

20+ years' experience in oil & gas operations

Serial entrepreneur - help build and crashed a drone start-up

ENDRE LINDEGAARD

Lead Designer

Electrician, CAD designer, 3D printer, welder and metal worker.

Our own MacGyver - 20 years experience as

Hands-on Problem Solver

ODA MARTINE KVERME

Design Enigineer

Design, systems, process and market analysis.

Keeps us on targe –

ensuring we do it right the first time

TOR WINCENT BYBERG

System Operator

Farmer and Process Technician

Deeply connected to the industry

Let’s work together.

Interested in working together?

Fill out some info and we will be in touch shortly!

We can't wait to hear from you!